Tactical pants are designed to endure an assortment of strenuous activities but also be presentable at the end of the day. Clothing makers address this challenge by employing a host of manufacturing techniques to improve the durability of their pants.

For this article, I reviewed about three dozen pairs of tactical pants by six different manufacturers. I specifically focused on the materials used to make tactical pants. In this article, I cover the fabrics, treatments, and weave styles used to design tactical pants, as well as the purpose of each application.

Fabric Materials for Tactical Pants

Manufacturers make tactical pants out of a variety of materials and weights so that the pants are comfortable for most conditions and temperatures.

Polyester and Cotton

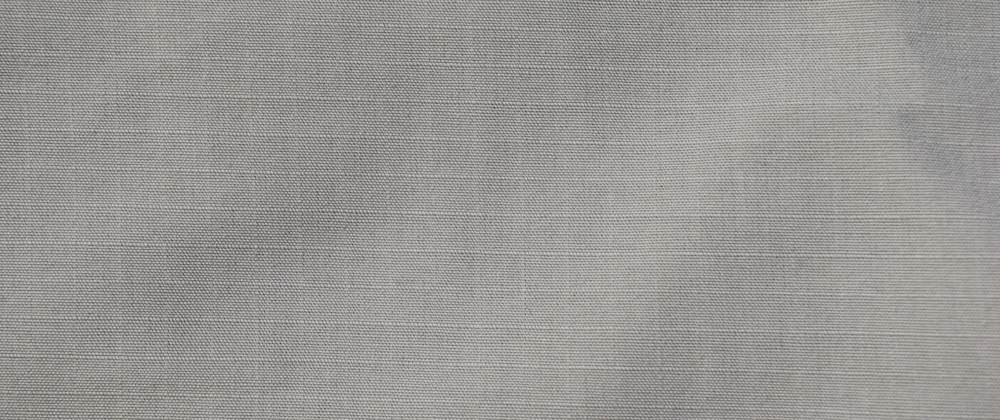

A 65 percent polyester and 35 percent cotton ripstop fabric.

The vast majority of tactical pants are polyester and cotton with a 65/35 combination. This all-purpose blend tries to capture the best of both materials. The synthetic polyester makes the pants more resistant to wear, moisture, wrinkles, shrinking, and fading while the natural cotton makes it softer and more breathable.

Nylon and Cotton

Nylon has similar, and in some cases, better qualities than polyester. It’s smoother, softer, and more water repellent. In fact, some manufacturers make their waterproof pants entirely out of nylon. However, nylon is also more expensive. Except for waterproof pants and some summer lightweights, the nylon and cotton blend is usually mostly cotton or a 50/50 mix.

100% Cotton

The biggest benefit of cotton, the original outdoor material, is temperature control. Depending on the construction, the fabric can keep you cool in the summer or warm in the winter. It’s also less likely to irritate your skin. You’ll usually find cotton tactical pants in a canvas or twill pattern.

A 98 percent cotton and 2 percent elastane twill fabric.

Of course, there are drawbacks to cotton. The fabric requires more maintenance and tender care than synthetic blends. Cotton clothes can shrink, so they need to be washed in cold water only or dry cleaned, and they’re definitely not wrinkle resistant, so you’ll have to iron them.

Other Materials

You’ll find a handful of other synthetic fibers mixed with cotton, polyester, nylon, or the blends mentioned above. For instance, you might see fire-resistant pants made with Nomex or Aramid, or, stretchy or flexible pants with lycra, elastane, or spandex.

Pant’s Weight

If you’re shopping online, pay attention to how the pants are described. Sometimes clothing makers will use terms like “lightweight” or “hot weather.” These are obviously intended for warm or hot weather. Sometimes though, the descriptions are not as obvious, so you have to pay attention to the actual weight of the pants.

Lighter pants are better for hotter temperatures and heavier pants are better for colder temperatures. One obvious indicator of hot or cold weather pants is the literal weight assigned to them. According to SewingIsCool.com:

- Lightweight pants weigh 1.5-5 ounces

- Medium weight pants weigh 5-10 ounces

- Heavy weight pants weigh 10-14 ounces

On average, tactical pants weigh about 6.5 ounces and tactical jeans usually weigh about 10 ounces.

Fabric Weaves for Tactical Pants

Fabrics are defined by the materials used to make them as well the patterns used to weave them together. The most common patterns include ripstop, twill, denim, and chino.

Ripstop

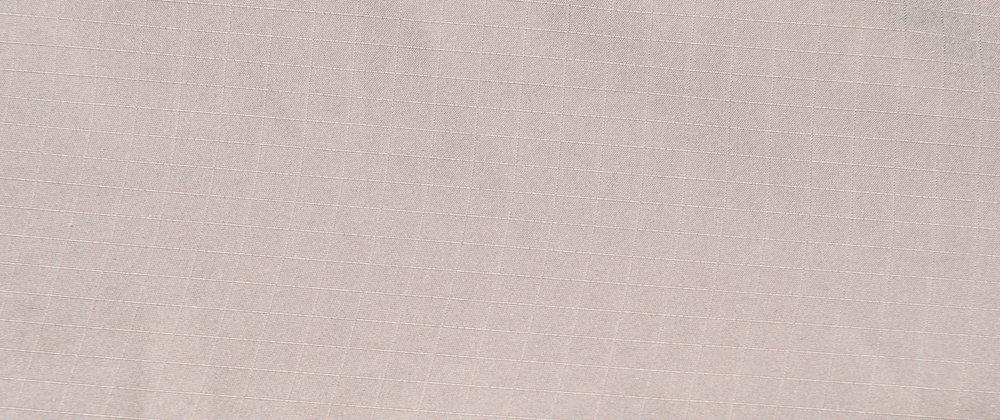

A 100 percent polyester ripstop fabric.

Ripstop fabrics are generally used for more duty-oriented tactical pants. The pattern makes fabric resistant to tearing and ripping, which is why it’s popular for tactical pants as well as parachutes, wingsuits, kites, etc. It’s also easy to identify. Ripstop uses a crosshatch pattern which looks like a bunch of squares.

Twill

A twill pattern looks like a bunch of parallel lines traveling diagonally. You’ll see twill tactical pants that include plain twill, denim, and chino. In other words, you’ll find more styles of tactical pants fashioned out of twill because a lot of clothes are made out of twill.

Denim

Tactical jeans are growing in popularity. Traditionally, denim is a cotton fabric, but if it’s marketed as stretch pants or flexible then it has been blended with a synthetic fabric like polyester or spandex. Tactical jeans tend to weigh more, usually in the 10-ounce range, and they’re designed more for function than storage.

Chino

Chino is a twill fabric traditionally made of cotton and most often used to make khaki trousers. The design has global origins. It started in China, was picked up by the British military, and later introduced into American fashion by U.S. troops returning home from the Spanish-American War. They’re just a basic pair of khakis.

Canvas

A 67 percent polyester and 33 percent cotton canvas fabric.

Canvas is a tightly-woven fabric. Compared to denim, canvas is more durable and nearly waterproof. It’s so durable that it’s often used to produce military gear. For tactical pants, you’ll find duty styles that look like military utilities, but there are also covert designs.

Treatments Applied to Tactical Pants

During the manufacturing process, a pair of tactical pants will likely undergo a couple different finishes to improve their overall durability. These include stain- and water-resistant treatments, and stretching.

Teflon

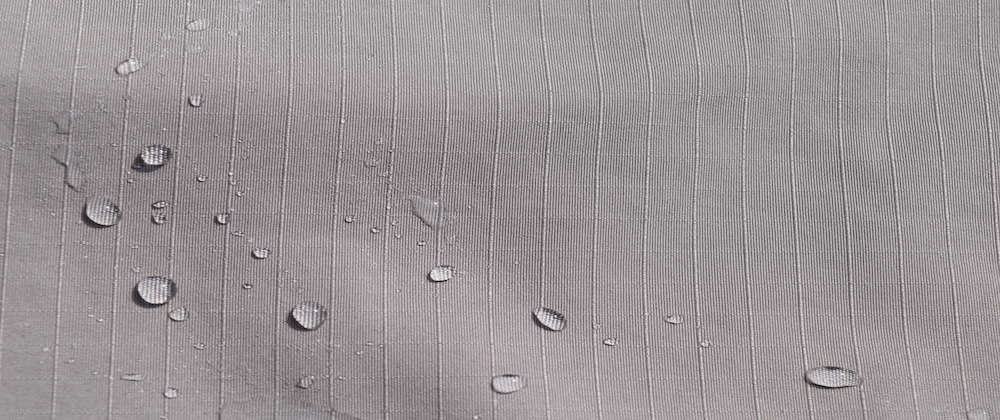

Water-resistant fabric.

Teflon is used to coat various products like cookware, cables, machine parts, and clothing. On fabric, teflon creates a stain- and water-resistant coat that’s easy to clean. Since it’s a brand, Teflon will be listed as a feature.

If tactical pants are marketed just as “stain resistant,” they probably underwent a proprietary treatment. Also, Teflon and other similar treatments fade over time and washings, so you may have to apply additional stain-resistant treatments.

Stretch

Stretchy fabric.

Stretchy fabric is growing in popularity because it makes moving a little bit easier. Manufacturers will make stretch tactical pants one of two ways. First, they’ll blend synthetic material like lycrane, elastane, or spandex, which are designed to stretch, into the fabric. And, second, they’ll apply a mechanical stretch finish to a polymer or nylon blended fabric after it’s been produced.

Blend It My Way

As you can see, tactical pants are available in a variety of fibers, weaves, and treatments. Personally, I like mechanical stretch canvas covert pants in coyote brown. What fabrics do you prefer in your tactical pants? Tell us in the comments below.

- Project ChildSafe: Distributing Gun Safety Locks Since 1999 - October 7, 2021

- Understanding Different Types Of Triggers & How They Work - August 24, 2021

- How To Draw A Pistol From A Holster Step-By-Step (Video) - August 24, 2021

Related Posts

« Beginner’s Guide to Guns: 4 Top Tips for New Firearm Owners Best Hunting Guns: What Should You Check Before Choosing a Firearm for Hunting? »